What are Gerber Files and how they are used in PCB Manufacturing?

What Are Gerber Files?

Gerber Files is the standard file used by PCB Manufacturing Company to fabricate a PCB to the required specification to describe the printed circuit board images: copper layers, solder mask, legend, etc.

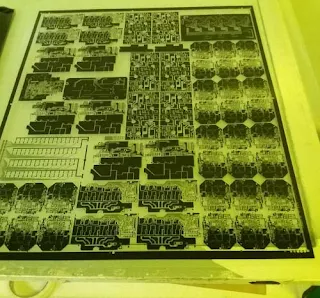

|

| JLCPCB Gerber Viewer |

A PCB Gerber file is a two-dimensional pictorial representation of each layer of a PCB board where tracks, pads, and vias are represented by different lines and shapes. It is the universal way of telling a machine how to create a PCB board based on the information provided. The Gerber File is the First Step of the PCB Fabrication Process.

It is a widely accepted PCB designing standard among manufacturers and customers.

Currently, many PCB manufacturers only support Gerber File. Taking JLCPCB for example,who is a popular PCB company and insists $2 for 1-4 layers PCBs.

JLCPCB only accepts Gerber files in RS-274x format for the copper layers, solder mask and legend layers, mechanical layer and SMD paste layers.

How Gerber Files Are Used In PCB Manufacturing

The PCB producing innovation utilized today has progressed significantly over the previous many years. Beforehand, vector photo plotters were utilized to make the tooling film utilized in the PCB fabricating measure. A shone light led through a gap was utilized to open the film to make the glimmers and draws for every individual cushion and follow.

There was just an insignificant arrangement of gaps accessible and planners must be innovative in confining their blazes and lines to just the gaps that were accessible to them. These more seasoned vector machines have now been supplanted by a fresher variety that uses a raster laser cycle to uncover the film. For bigger parts of film that had a ton of line drawing on it, a vector photo plotter could require numerous hours. This time has been chopped down to only minutes with a laser plotter.

Gerber document history can be followed back to the requirements of the first vector photo plotters. To give the plotter its guidelines, a Gerber record contained negligible plotter arrangement data, and X/Y organizes followed by a glimmer or drawing order and which opening situation to utilize. The Gerber information has expanded in usefulness throughout the year; it presently incorporates extra arrangement data just as full scale and opening definitions.

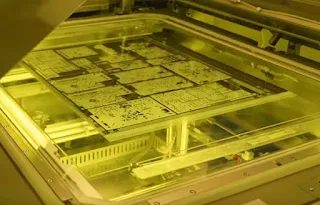

The laser plotters utilized today actually utilize a similar Gerber data, yet the opening limitations of the more established vector plotters at this point don't make a difference. The laser plotters convert the Gerber facilitates into a raster record, and that data teaches the laser plotter on how, where, and what is to be made on the movies. For instance, the opening definitions pass on the thickness and sizes of the follows and cushions while the drawing orders characterize whether lines, polygon fills or blazes are to be made. At that point the laser clears across the film uncovering the picture as it goes.

Time doesn't stand by however, and the universe of Gerber documents keeps on evolving. Circuit board makers have now started utilizing direct laser imaging to make PCB pictures straightforwardly onto the copper, and bypassing the requirement for movie. There are likewise new data set arrangements that are being utilized to make PCB pictures that contain considerably more canny board plan information, for example, net network information. However, it's protected to say that Gerber documents will keep on excess in its present structure for quite a while to come, and you should know about the part they play in PCB fabricating.

Instructions to Generate Gerber Files in a PCB Design

After your plan is finished and you've done the last check, the subsequent stage will be to create the Gerber records for your PCB producer. The way toward doing so fluctuates as indicated by the PCB plan programming that you're utilizing. Some more established instruments may find numerous ways to set up and produce records, however today, most CAD bundles have worked on the way toward making these documents.

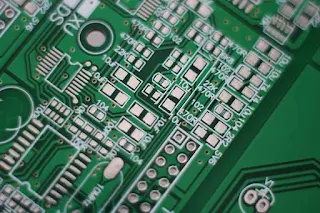

Normally the Gerber records you should create will be an individual document for each actual layer of the board. On the off chance that your PCB configuration is a six-layer load up with four sign layers and two planes for force and ground, at that point you should yield those layers into six Gerber documents. Furthermore, you should produce a different Gerber document for the top and base bind veil layers, the top and base silkscreen layers (whenever required), and the top and base weld glue layers (whenever required). The measure of silkscreen and glue layers will rely upon if your plan requires silkscreen and glue on both the top and the lower part of the board. A few producers may request extra Gerber layers for board layouts or creation and gathering data; however, those solicitations are for the most part for novel plan setups.

You will likewise have to arrange the Gerber record generator before you make the documents so the units, configurations, and guidelines are set up in a way that is steady with your plan norms and the principles of your maker. Albeit not a Gerber record, an NC drill document is normally made alongside the Gerber records. This record trains the boring machines utilized by the board fabricator where to penetrate the openings in the board. This record is basically the same as a Gerber-designed document in that it additionally contains drill size data and vector information for the diverse drill areas.

Conclusion:

Lastly, make sure to document your Gerber, NC Drill and other manufacturing files well so that your contract manufacturer can build the board according to your intent. You will need to create fabrication and assembly drawings, pick and place data, test data, a schematic net list, along with a readme file to finalize the process. The best thing that you can do is to work ahead with your CM to know exactly what it is that they need from you for the best results.

.jpg)

Post a Comment for "What are Gerber Files and how they are used in PCB Manufacturing?"

Dont use outgoing links!